The Internal Debug Board

The case of the

Openmoko

Neo 1973 and

FreeRunner

contains large pockets of

Embedded Air. Here is a little project that puts them to good use:

it integrates the principal functionality of the Openmoko

Debug

Board — USB access to a serial console and to

JTAG — into the Neo itself.

There is also an IDBG variant for the

Ben NanoNote.

Repository:

git clone https://github.com/wpwrak/idbg.git

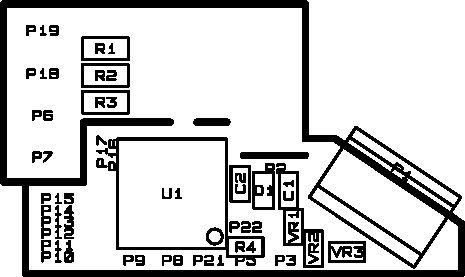

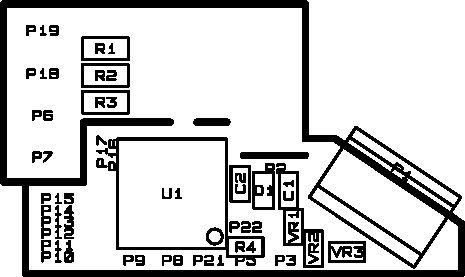

Design

The Internal Debug Board (IDBG) is designed to provide the following

features:

- Connects directly to USB (Micro-USB, for space reasons)

- IDBG firmware can be updated with DFU

- IDBG gives access to the Neo serial console

- IDBG gives access to JTAG

- IDBG can act as a master on the I2C bus

- IDBG handles the model-specific signals

nGSM_EN (GTA01) and nNOR_WP (GTA02)

- If it is not used, the IDBG is transparent to the rest of the system

Note that not all of this has been implemented and tested so far.

Illustrated build process

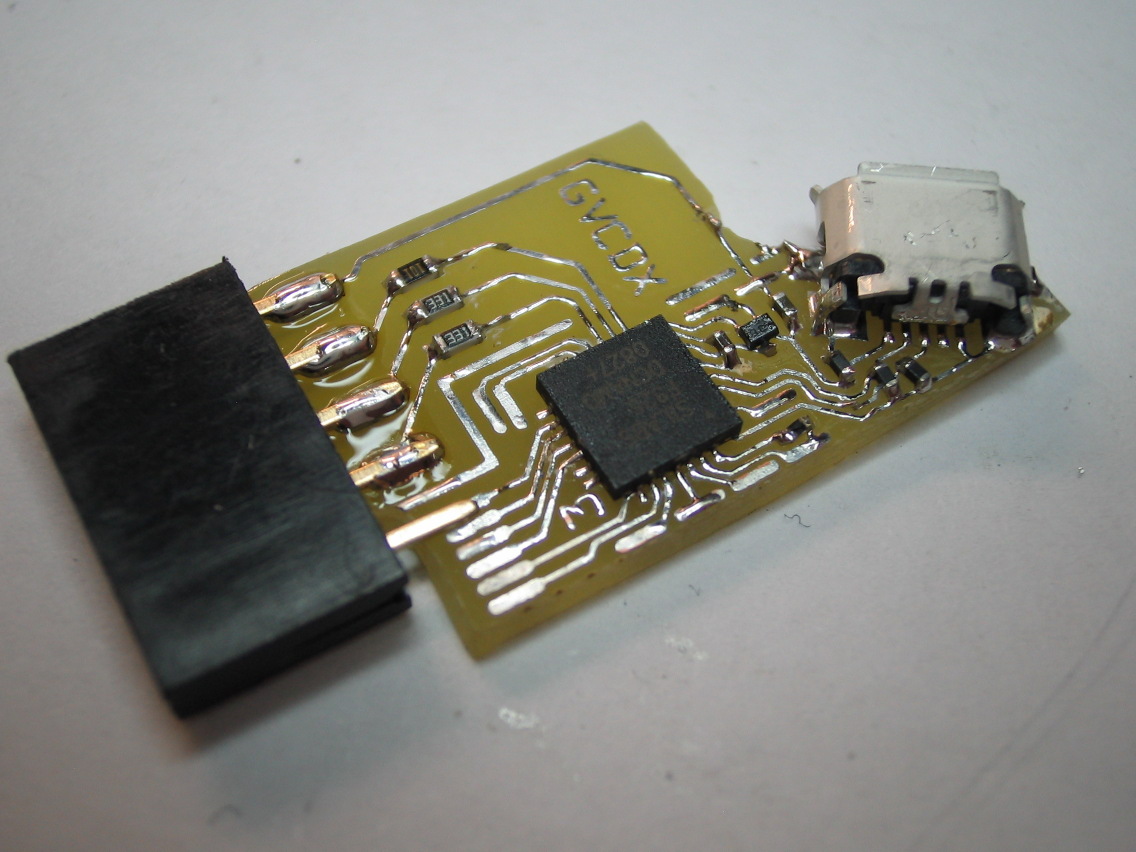

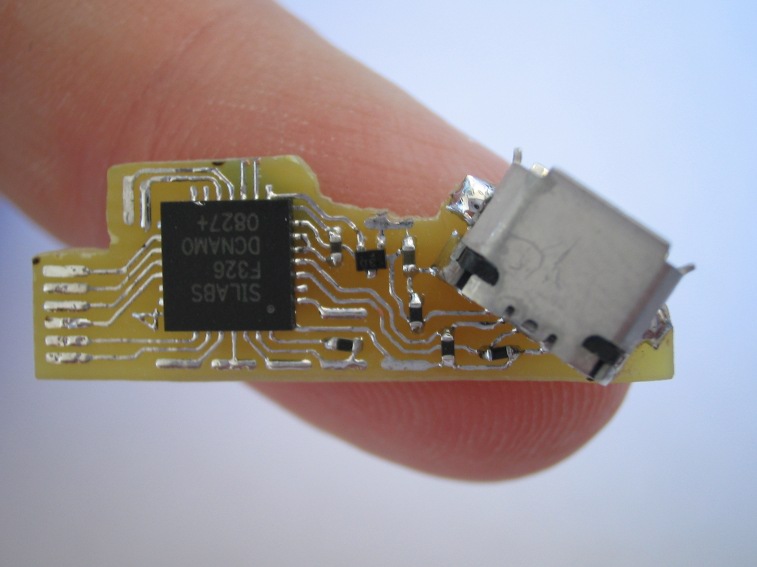

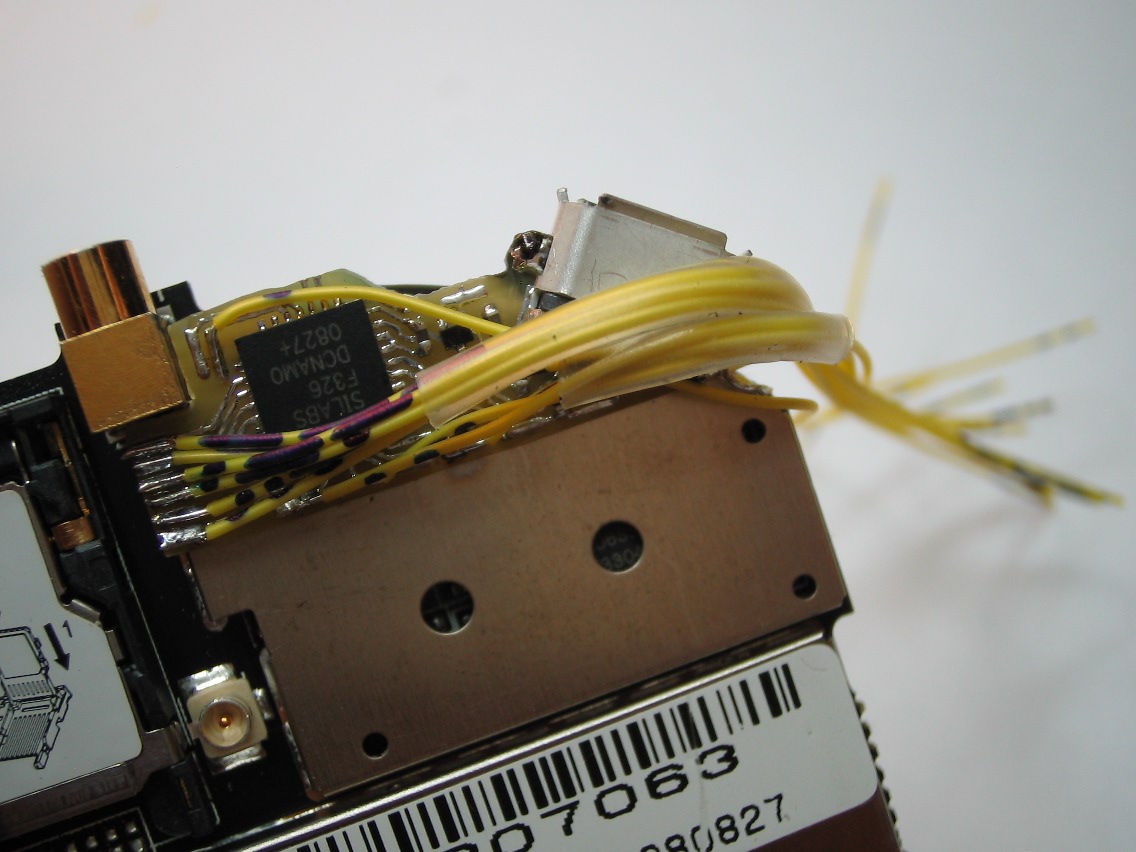

The board consists of a

SiLabs

C8051F326

microcontroller (QFN-28, 0.5mm pitch), the micro-USB B connector, and a few

discrete components (mainly 0402). The PCB itself is single-sided with 8mil

traces and 5mil clearance between traces. The circuit is designed for DIY

PCB production using the

toner transfer

method and manual soldering.

KiCad

sources for schematic and layout are in the repository.

Postscript versions of the files can be downloaded by clicking on the

images below.

IDBG comes with a sub-board that gives access

to the signals needed for programming the internal Flash of the

microcontroller. This sub-board is called the "IPL" board, for

Initial

Program Load.

On the left picture we see the IDBG board alone, on the right picture

it is mounted on a Debug Board v3 (v1 and v2 are not suitable but the

board could also be wired directly to the Neo).

In this configuration, power can be supplied

through a GPIO pin and basic communication with the microcontroller

is possible, e.g., to perform a boundary scan.

For Flash programming, USB must be connected to provide additional power.

A simple Flash programmer

called f326 that runs on the Neo is included in the git repository.

Please consult the README for further details.

After the initial programming, the IPL sub-board is cut off and the IDBG

board is glued on top of the GPS shield.

Next, we make a hole for the USB receptacle in the Neo's case. The

picture on the left shows the general lay of the land. Cutting the hole

is a process of trial and error and requires some patience.

It helps to remove only about a millimeter of material at a time and then

to check the position of the connector, as shown in

the middle. On the right, we see the final hole from the inside.

The result should look like my clumsy attempt on the left, but hopefully a bit

more precise and with fewer scratches. The IDBG's PCB may shine through if

the hole is too high. This can be hidden by painting the edge black with a

permanent marker. On the right, we see what the Neo now looks like. It is

important that the entire case closes properly.

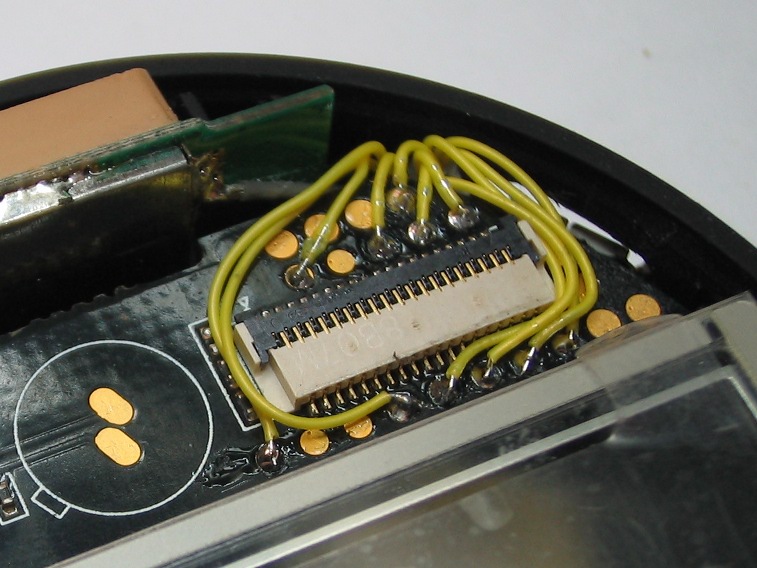

With the mechanics sorted out, we now return to the electronics.

A ground connection is added (this is the wire sticking out on the left

in the middle image below &emdash; here

is a better view of the ground connection) and thin wires are soldered

to all the pads used in this configuration. Marking both ends of each

wire with a "Morse code" as shown in the wiring diagram makes it easier

to make the right connections.

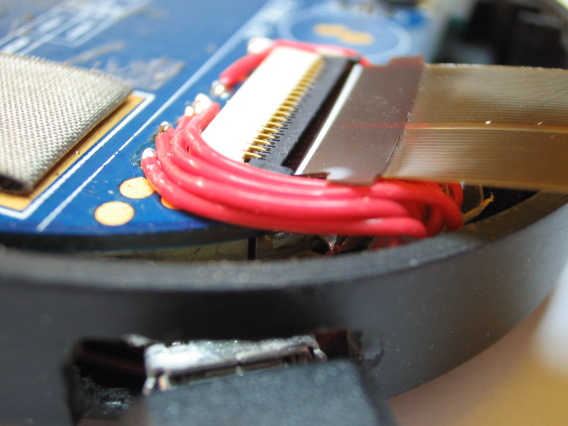

The wires are then bundled with heat-shrink tubing and brought across

the board edge to the top. (These pictures are from an earlier prototype,

hence the different color of the PCB and the much larger side hole, which

was made for Mini USB.)

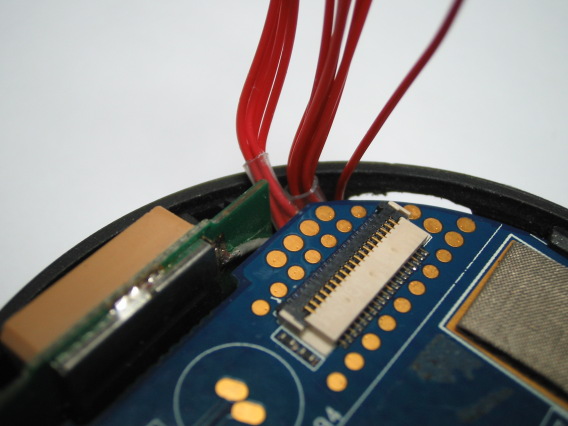

What follows is one of the highlight of the entire

operation, soldering the wires coming from IDBG to the test points on the

main PCB.

If we keep the path to the FPC connector clear, it's even

possible to have the internal debug board coexist with an external

one.

The wires shown above are stranded 30 AWG wires with an outer diameter

of 32mil or 0.8mm. This is about the thickest type of wire that can be

used &emdash; anything thicker would overflow the free space

under and around the board, and also the contacts on IDBG would be spaced

too closely. The images below show an alternative solution: wire-wrap

wires with a solid core that have an outer diameter of only about 20mil

or 0.5mm.

The main disadvantage of wire-wrap wires is their rigidity and thus a

higher risk of mechanical failure. The image in the middle also highlights

another problem: the isolation becomes very soft and vulnerable when heated.

If the wire is held down with a fingernail during soldering, the fingernail

may penetrate and damage the isolation. It's better to hold the wire with

something softer, e.g., the fingertip.

The last step is to close the case. There are some structures inside

the top cover that conflict with the new cables and must therefore

be removed. Their remnants have been marked with a yellow sheen in

the picture below:

The right-hand side contains almost exactly the same structures,

which are left untouched. Note that it is not necessary to trim the

plastic wall next to the LCM if the wires are thin enough.

Gee, it still runs !

Ben NanoNote

The version for the Ben is a bit simpler and has no JTAG or I2C.

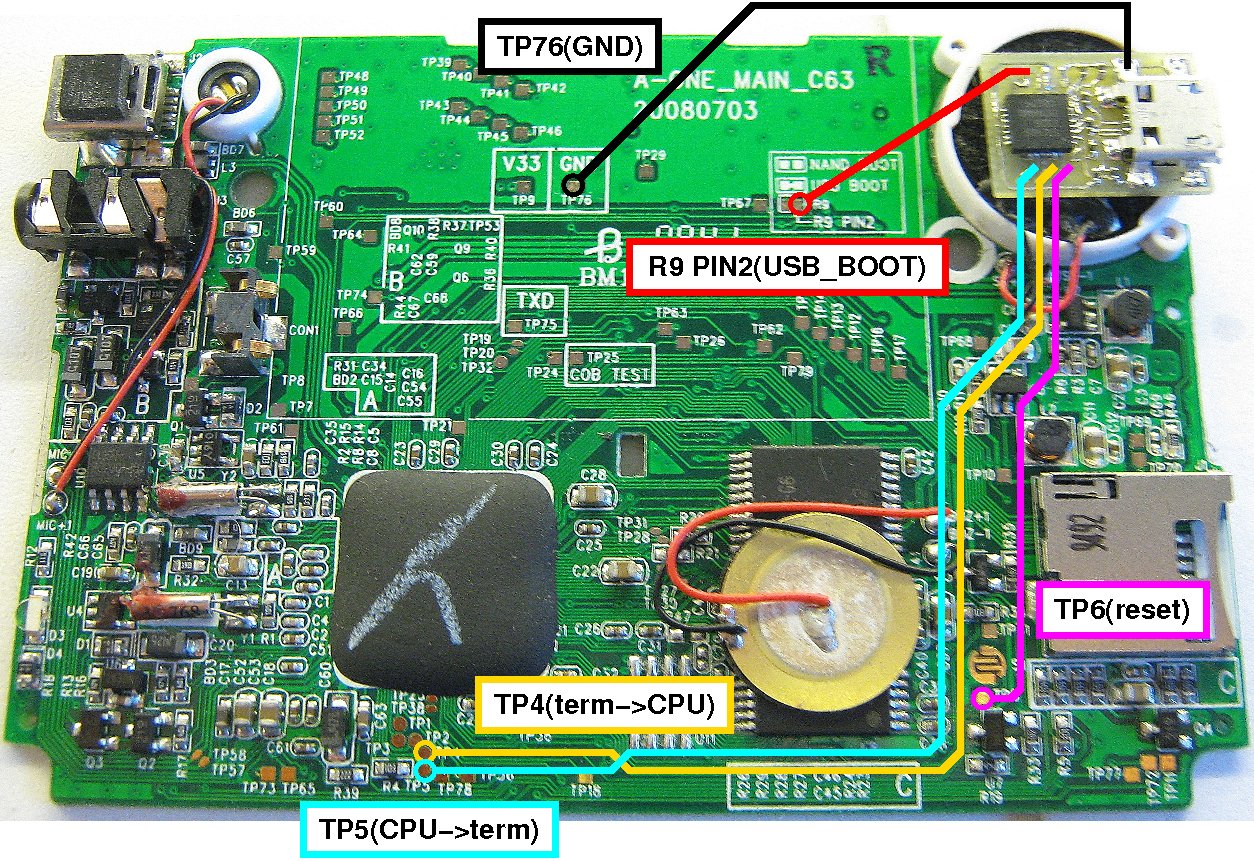

A Ben-specific addition is the connection to the USB BOOT signal.

This is what is looks like when installed:

![]()

Status

What works:

- Initial programming of the microcontroller's Flash

- Boundary scan through the

C2

interface

- Serial debugging output from the microcontroller

- USB enumeration in low-speed and full-speed mode

- IDBG firmware upload/download through DFU (with

dfu-util)

- Starting the IDBG firmware from the boot loader

- Read/write access to I/O pins through USB using the IDBG EP0 protocol

- Serial console at 115200bps

- JTAG with OpenOCD

- Read/write access to I2C devices through USB using the IDBG EP0 protocol

- Control of nNOR_WP in GTA02 through command-line utility

- If unpowered, IDBG leaks only about 10 nA through GPIOs

- f386 -p protects the boot loader from being clobbered by the firmware

What's untested or not yet done:

- Operation with IDBG connected to VSYS, especially power consumption

- GTA01 UART sharing with nGSM_EN

- Monitoring of nRESET for automatic JTAG detach

- Testing on GTA01

- Effect on GPS performance

- Find out what descriptors to use for serial console

Known bugs:

- DFU upload causes stray stalls if sending EP0-sized packets

- f326 sometimes locks up (work-around: just try again)

- Organization of code and repository isn't nice

- Need more fine-grained licensing, e.g., CC for schematics,

LGPL for libraries

- Flow control of serial console is broken in the host to target direction

For further study:

- IDBG should be able to command the PMU during power-up,

e.g., allowing it to limit inrush current and to override PMU

settings.

The idea is as follows:

- connect IDBG VSYS to the PMU's SYS1/SYS2

- remove SYS1/SYS2 from VB_SYS

- connect SYS1/SYS2 to VB_SYS through a switch, e.g., a

Fairchild FPF1003A or similar.

- control the switch via IDBG FUTURE

Since VB_SYS is hard to interrupt on GTA02, the idea could be tried by

switching only IO_3V3.

- Could we merge USB power from IDBG into VBUS ?

Some considerations:

- The PMU does not support "merging" USB and adapter power.

If adapter power is present, it takes precedence over USB.

- If we merge directly into VB_SYS and main USB is not connected,

the PMU will not charge the battery.

- If we merge into VBUS, we can share the PMU's USB current limiter.

However, if the limiter was set to the sum of the inputs, we would

overload the remaining input if the other one is disconnected.

To prevent this, we would either have to draw power from only one

USB source at a time or have external current limiters on both.

- If GTA02 provides USB power, this power is taken from VB, so

there is a conflict with accepting power from another party. We

could probably connect U4904 to VB_SYS.

- If we merge into USB_VBUS, we could feed the USB output

directly but would lose the reverse current protection of U4905.

- Could IDBG snoop the I2C bus and report transactions ?

- Consider adding special serial console functions. Some ideas:

~r to reset (GPIO), ~p to power down (PMU),

~d to dump the log buffer from a crashed kernel (JTAG), ...

Werner Almesberger,

05-MAY-2014